Nā pūʻolo holoi mālama hale

Hoʻopuka kūpono

ʻO ka wai hoʻoluʻu i nā kihi a pau, ka hoʻoluʻu wikiwiki a me ka ʻaʻahu, e hauʻoli i ka manawa pōʻai wikiwiki loa a e hōʻoia i ka maikaʻi o ka ʻōmole.

ʻO ka maikaʻi o ka ʻōmole

1, paʻa ikaika, ʻaʻohe leakage

2, ʻO ka halihali lōʻihi, ka hāʻawi haʻi ʻana, a me nā mea ʻē aʻe, hāʻule i ka honua me ka haki ʻole.

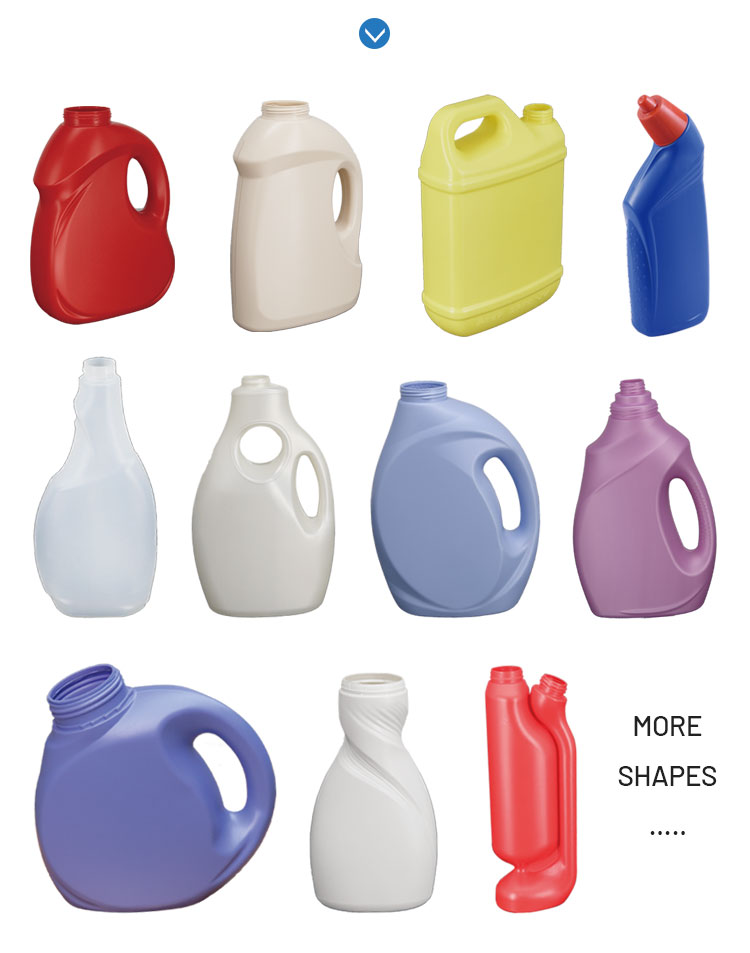

Hiki ke hoʻopilikino ʻia kēlā me kēia hoʻolālā.

Desgin mai ke kiʻi nui a hiki i nā kikoʻī

Laina Huahana

Kahi o ke kumu: Guangdong, Kina

Ka inoa Brand: Hoʻokahi

Ka helu kumu hoʻohālike: XP2101789

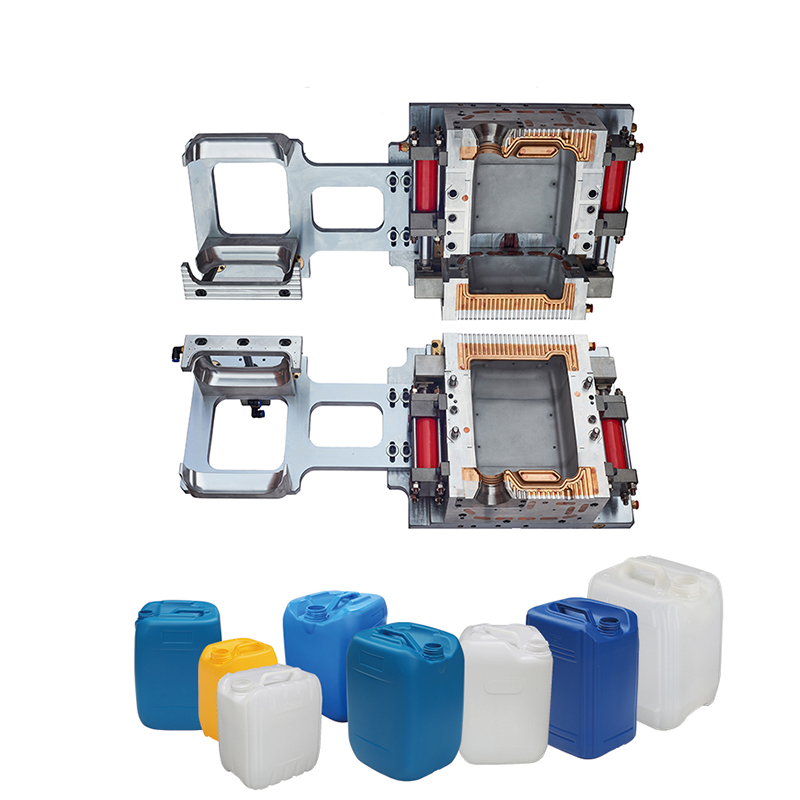

Ke ʻano hoʻoheheʻe: Puhi ʻana i ka Mold

Mea Huahana: Aluminum + Becu

Huahana: Huahana hale

Ka inoa o ka huahana: puhi ʻana i ka hdpe

Kawaha:1*4

Noi: puhi i ka hdpe

Mea palaki:HDPE

Koho mea mold: 45 #, 50 #, P20, H13, 718, 2738, NAK80, S136, SKD61 etc.

Lapaʻau ʻili: Polina

Ola mold: 2 makahiki

Mold base: HASCO standard, European standard, World standard

Mea lako:CNC, Lathe, EDM, Wire Cutting, Drilling, etc.

Hiki ke hoolako

Mea hoʻoheheʻe i makemake ʻia

| Beryllium bronze - nā ʻāpana ikehu kino a me ka mechanical | ||||

| inoa Becu | Be-275C (C17100) | BeA-20C (C17200) | BeA-1C (C17500) | BeA-50C (C17600) |

| Māmā g/cm(20°C) | 8.09 | 8.3 | 8.62 | 8.62 |

| ʻO ke kau wela wela w/mk(20°C) | 100 | 105 | 195 | 210 |

| Ka ikaika uʻi MPa | 1140 | 1105 | 660 | 705 |

| ʻO ke koʻikoʻi% | 1070 | 1035 | 520 | 520 |

| ʻO ka elongation | 1 | 1 | 6 | 8 |

| ʻoʻoleʻa | HRC46 | HRC43 | HRB96 | HRB96 |

| 2ACS% | 15 | 18 | 45 | 45 |

| Nā waiwai o ka beryllium copper | Loaʻa i ka Beryllium bronze nā waiwai piha maikaʻi.ʻO kona mau ʻano mechanical, e like me ka ikaika, ka paʻakikī, ke kūpaʻa a me ke kūpaʻa luhi. ʻO ia ka mea kiʻekiʻe ma waena o nā alloy keleawe, a ʻoi aku ka nui o ka conductivity thermal ma mua o ke kila a me ka alumini. | |||

| Ka hoʻohana ʻana i ka mold extrustion blow molding | ʻO ka milo, ka ʻāʻī, ka lima a me ka hoʻokomo ʻana i ka lihi ʻoki lalo, ka pine | |||

| Nā waiwai a me ka hoʻohana ʻana o 7075 magnesium alumini alumini | ||||||||

| haku mele ʻana | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti |

| ≤0.4 | ≤0.5 | 1.2-2.0 | ≤0.3 | 2.1-2.9 | 0.18-0.28 | 5.1-6.1 | ≤0.2 | |

| Nā waiwai kino | Coefficient o ka lawe ana i ka wela | 0.2%Hiki i ke kaumaha Rp0.2 | Oolea HB | ʻO ka elongation | Modulus o ka elasticity | ʻO ka mānoanoa | Ka ikaika tensile | Wela kūikawā |

| 173W/mK | 455Mpa(N/mm²) | 150 | ≥6 | 71GPa | 2.81g/cm³ | 524Mpa(N/mm²) | 0.96J/gK | |

| Nā hiʻohiʻona | 1, Kiekie-ikaika wela-treated alloy 2, Na maikai mekini 3, maikai loa thermal conductivity 4, maalahi i ka hana, maikai aahu pale pale 5, maikai corrosion pale a me oxidation. | |||||||

| Ka hoʻohana ʻana i ka mold extrustion blow molding | Cavity, delashing, delashing oki | |||||||